Overview

The Ricardo transaxles came from the Ford GT program when Ford asked Ricardo (in the UK) to build a bespoke transaxle for their halo car of 2005-6, the Ford GT. The gearbox Ricardo produced -in record time- was the only modern transaxle (6 speeds, advanced triple-cone synchronizers, internal oil pump, very high input torque rating, etc.) in recent memory that was designed for mid-engined use in very high torque V8 engines, at least at an affordable price point.

Ricardo did the transaxle work under extreme time pressure, and featured the transaxle in one of their quarterly publications, which is available here: FordGTCaseStudy.pdf

Sources

These transaxles can occasionally be sourced from eBay, typically from wrecked Ford GTs. For a while after they were first produced, some people reported that about one Ford GT per day was being wrecked, so the supply at that time was decent. However, most of the ones that remain are in the hands of owners that have had them for a while, and haven't wrecked them yet, so that rate of destruction is likely not to repeat itself. And because prices of the Ford GTs have remained high, more of the wrecked cars are being rebuilt, making the transaxle supply problem worse.

There was a source in Europe that was using NOS parts and transaxles from Ricardo, and rebuilding them. However that person has passed away, and there are no more units available from him. The Ricardo transaxles have very limited availability, but are generally thought to be the best transaxle for high-powered cars. Ford supposedly has a very small number of new ones in stock- at a reputed price of $17,000, plus a core.

Recently Ford has been requiring proof of ownership of a GT as a precondition to filling transaxle orders, so the only realistic options are eBay or other used sources. As of 2018, some builders have reported that Ford is requiring proof of ownership of a GT (i.e., current registration) in order to buy any GT-related parts, even including seemingly common parts like clutch slave cylinders and starters. As a result, there are now some aftermarket sources for certain parts. Centric now makes a clutch slave cylinder for the GT, and it is available from sources as varied as JC Whitney.

Only a few shops are really capable of working on these semi-exotic transaxles, but many of them have passed through RPM Transmissions. Some people have reported good results with Ron McCall. Avoid any dealings with DeLynn Mason or Erik Johnson as many builders have had bad experiences.

Technical

The transaxles have 6 forward speeds, triple synchros on most gears, have a torque-sensing limited slip, and an integrated oil pump and ports designed for an external oil cooler. The crownwheel is huge for a street transaxle, which is one reason why they are among the heaviest units, weighing in at around 200 lbs dry.

Several Ford GT owners have built their cars to over 1,000 HP, and there are no reports (of which we are aware) of power-induced transaxle failures. These are probably the strongest transaxles available for the SL-C.

A portion of the workshop manual can be found here.

A complete set of Ricardo drawings for this transaxle is available here: Ricardo Diagrams.pdf

Gear ratios are:

| First: | 2.611 |

| Second: | 1.708 |

| Third: | 1.233 |

| Fourth: | 0.943 |

| Fifth: | 0.767 |

| Sixth: | 0.625 |

Final drive ratio is 3.36, but Stillen made a small run (<25?) of much shorter final drives which gave even greater acceleration. These are NLA, but used ones may be available. A good place to search is the Ford GT forum.

The stock gear ratios are ideal for a street-driven car, as they were selected for a powerful, torquey V8, and yield a very high top speed combined with potentially good fuel economy due to the upper three gears being overdriven. Race gearing would be much shorter. Another goal for the Ford GT was a low 0-60 MPH time, so it would get good magazine coverage. Thus, the car was geared so that 60 MPH could be achieved in first gear, saving a shift that would have added tenths to the published times.

The reverse switch for the Ricardo closes the circuit when reverse is selected. It uses a standard 2-wire weatherpack connector. The switch is a generic Ford part, with a Motorcraft number of SW-6205.

The Vehicle Speed Sensor (VSS) uses a pigtail from, supposedly, a T5 transmission. Standard Motor Products part # S699 is a pigtail that can be used.

Shifter and Shift Cables

The transaxle can be shifted with either the now-standard Brandwood shifter, or the original Ford GT shifter (including the difficult-to-find short shifter). The shifter cables are provided as part of the SL-C kit, but because the builder can route them in different ways, and mount the shifter in different places, the cable length can't always be known in advance. The norm is to mount the shifter where you want it, route temporary "cables" made from clothesline and find the nominal length from the shifter to the bracket on the transaxle. That is the length Superlite needs to order the correct cables.

The cables may seem too short when delivered, but this can be managed by using adapters and nuts to fine-tune the connection to the actual transaxle arms. Note that by adjusting the balls connectors on the transaxle arms, the effect of a "short shifter" can be obtained.

The shifter thread size is M12 X 1.75.

The clutch uses a standard Ford Mustang clutch alignment pilot tool. One can be obtained from OTC- their part number is 308-599, and it can be sourced from eBay or Amazon for under $20.

Installation Issues

Because the transaxle is designed for a mid-engined application, no inversion or other changes are needed, unlike the typical Porsche 911-based transaxles.

Issues

Early Ford GTs had a batch of defective axle bolts, which tended to break due to an incorrect heat treatment from a supplier. Most of the existing transaxles have had the correction, but all of these transaxles should be inspected to be sure that the upgraded axles bolts (and washers) have been installed. If you can't be sure, replace them with the Ford kit, or the ARP-sourced kit from Accufab. Repair parts are non-existent from Ford or Ricardo, with a few people holding some damaged transaxles in inventory for use as parts.

Here is a picture of a Ricardo transaxle with the defective axle bolts installed. One bolt has already started to back out here...

And another in which one of the bolts has already lost it's head...

A failure of these bolts under load at speed could be deadly. Be sure you have upgraded these on your transaxle.

To tell if you have the right bolts and washer installed, read the following PDF here: axlebolts.pdf This PDF also has the correct torque specs.

The axles from Superlite use the popular and very strong 930 CV joints. These have a different size bolt circle than the transmission bells and so adapters are a standard part of the axle package. The bolts on these adapters must be torqued to 57 ft lbs per The Driveshaft Shop, providers of the axles.

Pilot Bearings

When interfacing the LS engine to the Ricardo, a custom flywheel is usually used. This can be supplied by Superlite. The flywheels have a machined hole that is designed to insert a bushing or bearing, replacing the normal pilot bearing in the crankshaft with a conventional setup.

If you use a pilot bushing, wrapthe custom brass pilot bushing, which you can obtain fromSuperlite Cars, in a plastic bagand put it in the freezer for a couple of days to make sure it is as cold and small as possible.

Some cars were provided with a brass bushing, and later cars may have come with a brass bushing with an integral roller bearing as shown here:

Another option is to use a traditional pilot bearing. There are a couple of options for such bearings. Grainger sells a bearing with part number 1ZGH3, which is a China-sourced bearing for less than $7. Another source is a bearing from Lakewood, which is made domestically, and carries part number 15975. This bearing is available from Speedway and others. The inner diameter for the input shaft is correct, but the flywheel will have to be machined to fit the outside diameter of either of these two bearings, both of which carry identical dimensions. The Lakewood bearing is typically around $30, but appears to be of higher quality.

Clutch

The Ricardo uses the Ford GT clutch, which is a multiplate clutch available from Ford dealers. Stillen also provides a slightly stronger variant for more powerful engines, although the stock clutch is apparently able to take over 600 HP. You'll also need to obtain the 9 clutch-to-flywheel bolts. Unless you have a Ford Modular engine, you will need a custom flywheel to adapt the engine to the Ford GT clutch. If you are using the Stillen clutch, the flywheel needs to be relieved slightly to allow for its thicker rivets. Check with the factory to be sure your flywheel is appropriate for your clutch. Using any aftermarket clutch with stringer springs will likely mean that you will need a different size master cylinder to keep the factory effort, so plan accordingly.

For a GM LS engine install the custom flywheel from Superlite Cars to the engine using the standard GM flywheel bolts. Note that the holes in the crank where the flywheel is attached are not symmetrical. Rotate the flywheel until all the holes in it line up with the tapped openings in the crankshaft. If your flywheel has the appropriate holes, install a factory locating pin as well. Torque all bolts to factory specs for your engine. These may be torque-to-yield bolts, so don't reuse them.

When the flywheel is installed on the engine, install the clutch to the flywheel using the 9 long bolts. The discs in the flywheel will need to be aligned using a standard Ford clutch alignment tool available at any Ford dealer, or on eBay. Torque these according to the factory specs [ASW1] in the Ford GT manual. The red straps holding the clutch together from the factory will loosen as the clutch is torqued and should be discarded before joining the transaxle to the engine.

Join the engine and transaxle using the adapter plate, including the necessary pins and bolts. This is a delicate process, and should not be forced. If the transaxle does not slide onto the engine cleanly, try to rotate the engine or the transaxle output shafts to help align the input shaft to the clutch. Attach the adaptor plate to motor with 6 ea. M10-1.50 x 45mm bolts, flat and spring washers. Torque to 44 Nm.

Do not help the transaxle to be joined to the engine by tightening up the bolts to the adapter plate. This will only cause damage to the transaxle, clutch or engine.

Ancillaries

In addition to their high cost and very limited availability, these transaxles require a specific Ford GT starter (around $275 now, down from as much as $650) and the factory dual-disc clutch (about $1900). RCR/Superlite sells a custom adapter place to mate up the popular LS-series engines with the transaxle.

The clutch slave cylinder is internal to the case, and has a metric fitting. The proper m10 X1.0 to -3AN fitting can be obtained at Pegasus and other stores. This fitting allows a regular -3 AN line to be attached to the slave cylinder directly, and replaces the original line with the foil covering.

When mounting the Ricardo to the adapter plate you will need 2 alignment pins (f5rz-6397-c dowells @ $4.16 ea) available through Ford. There are nine clutch bolts (-n806178-s437 bolts @ $3.00ea) and you will use 6 Qts 75W-90 synthetic lube (xt-75w90-qgt oil @ $35.50ea). Note that this oil part number is for the Ford GT specific oil. The consensus on the Ford GT forums is that only the factory transaxle oil should be used-- no other oils have the specific additive package that Ricardo specified. The cost and rarity of these transaxles is another reason to use the factory-specified oil, as an oil-related failure is likely to result in a complete transaxle change as there are essentially no repair parts for these units. The oil can be acquired from Ford dealers (make sure you check to be sure your oil has the correct part number as many parts people don't know the difference) or from Amazon.

Visuals

Not with standing the text in the picture, these are not now readily available...

Here is a picture of an engine with a clutch for the Ricardo attached:

Note the use of a Ford clutch alignment tool, which is necessary to align the clutch pack so that the assembly slides onto the transaxle input shaft. Also note the adapter plate to mate the engine to the transaxle.

The electrical connections for the Ford GT40 starter are shown. The D-shaped single spade pigtail part number has been identified by Mesa and Kens80V as from a V6 Camry, or similar Japanese engine.

Here's a link to one.

This is the T56 Reverse Light Weatherpak connector. It's just half of a regular 2-wire weatherpack.

This is the S699 Speed Sensor Connector. These can be obtained at local parts stores.

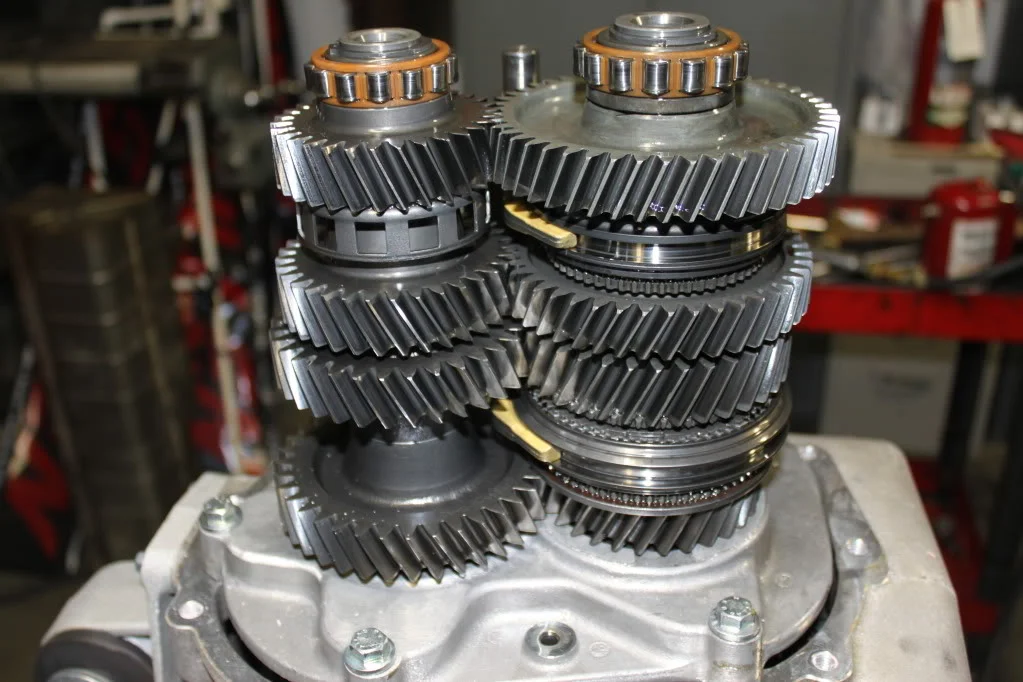

Here are some pictures of a Ricardo transaxle that is being rebuilt with old parts.